Offshore and marine projects require materials that can withstand constant stress, salt exposure, and heavy loads. Carbon steel plates remain a popular choice among shipbuilding and offshore yards for builders who prioritize strength, dependability, and cost management. These plates are the base of ships, platforms, and marine structures that must withstand sea water for a long-period of time. Their balanced mechanical properties support safe operation in harsh conditions, where failure is not an option. This blog explains why carbon steel continues to dominate marine construction. It covers material basics, common grades, key applications, and the practical benefits that make these plates a trusted solution across shipbuilding and offshore fabrication.

What Are Carbon Steel Plates?

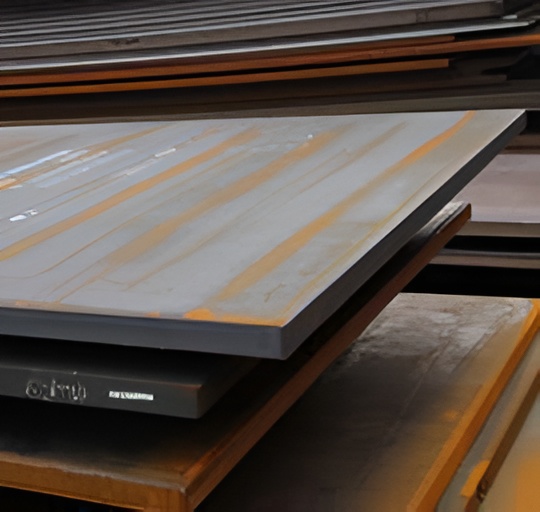

Carbon steel plates are flat steel products consisting of iron and carbon, with trace amounts of other components. The carbon content determines strength, hardness and welded performance. Lower carbon grades are more flexible, and easier to weld, which makes them ideal for marine manufacturing. These plates exhibit high tensile strength, strong toughness and consistent load performance. Surface treatments, and coatings increase resistance to seawater exposure. In shipbuilding, ASTM A36 plates are a common structural grade. This specification ensures constant strength, ductility, and smooth fabrication finishes. These features explain why carbon steel plates are suitable for marine structures that experience bending, vibration, and repeated stress cycles.

Applications in Shipbuilding and Offshore Industries

Carbon steel plates support a wide range of marine and offshore structures. Their versatility allows use across primary structures and supporting systems.

- Ship Hulls & Deck Structures: Hulls and decks depend on high-strength plates to handle wave impact and cargo weight. Carbon steel plates provide the stiffness needed to maintain shape under constant motion. They also support welding of large panels without distortion, which improves build accuracy.

- Offshore Platforms & Oil Rigs: These structures face constant waves and wind. Builders use heavy-duty steel for the main frames and supports to ensure the rig stays stable even during severe storms or underwater shifts.

- Marine Equipment & Machinery: Tanks, hoppers, and machinery bases often use carbon steel plates. These parts require strength and ease of fabrication. Carbon steel allows precise cutting and welding, which supports tight tolerances in marine systems.

- Fabrication Projects: Docks, jetties, bridges, and offshore walkways depend on durable steel plates. Carbon steel supports large spans and heavy traffic. Its performance under variable weather makes it suitable for fixed marine infrastructure.

Advantages of Using Carbon Steel Plates

Carbon steel plates offer significant advantages for marine and offshore applications. Its performance, affordability, and ease of application explain why builders continue to use them in many other materials.

- High Strength and Toughness: Carbon steel can carry heavy loads and handle sudden shocks. This is important in rough seas and active ports. The material stays stable under stress and helps maintain structural safety over long service periods.

- Cost-Effective Material Choice: Carbon steel costs less than stainless steel or alloy grades. It offers strong performance without high material or processing costs. For large vessels and offshore structures, this helps keep total project expenses under control.

- Ease of Fabrication: Carbon steel plates are easy to cut, weld, and shape. Standard tools work well with this material. Faster fabrication reduces delays and improves build efficiency in shipyards.

- Long Service Life: With proper surface protection, carbon steel performs well in marine conditions for many years. Coatings and corrosion control systems slow material wear. This helps extend service life and lowers long-term maintenance costs.

- Reliable Supply Chain: Sourcing from experienced carbon steel plate suppliers provides consistent quality and quick delivery. The continuous supply of materials improves effective project planning and reduces construction-related risks.

Conclusion

Shipbuilders continue to rely on Carbon Steel Plates for offshore, and marine projects as they offer strength, cost control, and easy fabrication. These plates support hulls, decks, and platforms that face constant stress from waves, loads, and weather at sea. ASTM A36 plates remain a preferred grade due to steady performance, wide approval, and smooth fabrication. Even under extreme marine environments, carbon steel offers a long service life when properly protected. Shipbuilding relies on standard materials for maintaining ships and offshore structures, and carbon steel meets these needs while balancing performance and cost. Working with professional Carbon Steel Plate Suppliers on new constructions, or repairs ensures quality, compliance, and dependable results for marine, and offshore projects.