The construction industry is one of the most important sectors of the economy. Apart from employing millions of people, it also plays an important role in developing communities. This is why construction companies need to use strong and durable materials. One such material is the abrasion-resistant wear plate. It is a type of steel plate that is designed to withstand the effects of abrasion and impact. This blog will discuss the advantages of using abrasion-resistant wear plates in construction and infrastructure projects.

What are Abrasion Resistant Wear Plates?

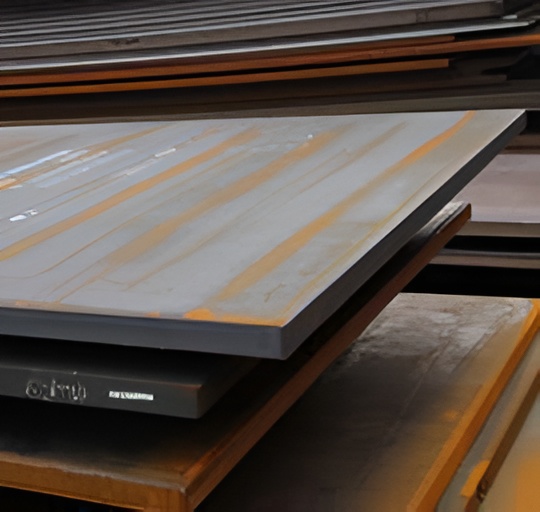

Abrasion Resistant (AR) Wear Plate is a steel plate designed and fabricated to resist severe abrasive wear. The plate’s surface is comprised of various elements, such as chromium, manganese, carbon, and boron, which all combine to create an extremely durable material capable of withstanding extreme abrasion. Due to its unique characteristics, AR Wear Plate can be used across various industries, including mining, cement, construction, and agriculture.

Advantages of Using Abrasion Resistant Wear Plate

Durability

Abrasion-resistant wear plates are highly durable and can withstand heavy impact and abrasion. They are made of a special type of steel that is much harder and stronger than regular mild steel. This makes them ideal for construction and infrastructure projects where the equipment must constantly be exposed to harsh conditions.

Increased lifespan

Using abrasion-resistant wear plates can significantly increase the lifespan of construction and infrastructure equipment. The wear plates protect the underlying structure from damage, corrosion, and erosion. This means the equipment will last longer and require fewer repairs and maintenance.

Reduced maintenance costs

As mentioned earlier, using abrasion-resistant steel wear plate can reduce the need for repairs and maintenance. This can save construction companies much money in the long run. In addition, these plates are easy to replace, so any damaged plates can be replaced quickly and easily.

Improved safety

When equipment is exposed to heavy impact and abrasion, there is always a risk of accidents. However, the use of abrasion-resistant wear plate can significantly reduce this risk. This is because the plates provide an extra layer of protection, which can prevent accidents and injuries.

Better performance

Abrasion resistant steel wear plates can improve the performance of construction and infrastructure equipment. This is because the plates reduce the amount of wear and tear on the equipment, which means that it can operate more efficiently. This can lead to increased productivity and lower operating costs.

Conclusion:

Abrasion-resistant wear plates are an excellent choice for construction and infrastructure projects. They are highly durable, can increase the lifespan of equipment, reduce maintenance costs, improve safety, and enhance performance. Using these plates can lead to significant cost savings and improved efficiency for construction companies. Therefore, It is essential to consider abrasion-resistant wear plate in any construction and infrastructure project.